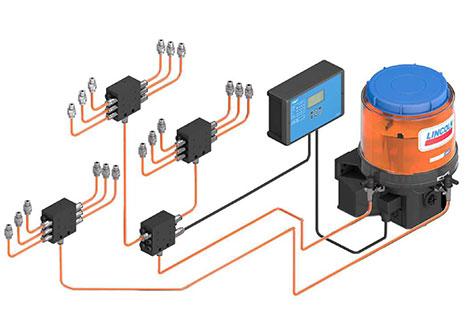

Progressive Lubrication System

Progressive lubrication systems are the ideal solution for small to medium machines that require continuous lubrication. The lubrication continues as long as the pump runs. Once the pump stops, the pistons of the connected progressive distributors remain in their current positions. When the pump resumes the transfer, the pistons resume their movement from where they stopped.

A special monitoring feature of these systems is that the lubrication circuit connected to a pump element is blocked once a single lubrication point is blocked. To monitor a lubrication point, it is enough to visually or electrically monitor a piston of a progressive distributor connected to the same pump element. The type of monitoring depends on the distributor used.